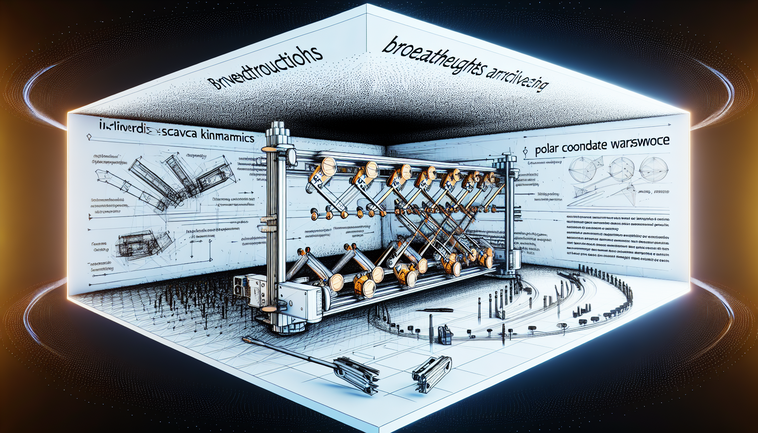

When breakthroughs arrive in unexpected shapes and motions, the 3D printing community takes notice. A newly revealed machine brings together inverse SCARA kinematics with a polar coordinate workspace, creating a truly unconventional platform for additive manufacturing. Instead of the familiar Cartesian gantry, this design spins two rotary disks to position the printhead, showcasing how fresh thinking can drive desktop fabrication forward.

At the heart of this project lies an inverse SCARA arm, flipped into a polar arrangement where two independent disks serve as motion stages. This configuration trades linear slides for rotational axes, offering a compact footprint and potentially smoother continuous motion. Watching the machine build intricate models reveals a mesmerizing choreography of spinning plates and a nimble print tool weaving plastic threads in midair.

Perhaps its most compelling feature is the on-the-fly toolchanger. By mounting multiple nozzles on a rotating turret, the printer can switch between different extrusion heads without manual intervention. This capability unlocks multi-material prints, varying nozzle diameters, or even hybrid processes that combine plastic deposition with pen plotting or light curing, all in a single job.

Mechanically, a polar dual-disk system trades the familiar X-Y rectangle for a pair of concentric circles. The inner disk can carry the tool turret while the outer disk supports the build platform, or vice versa. Synergizing their rotations allows the printhead to sweep across the workspace in spiral or radial paths, reducing the need for rapid direction changes and cutting down on vibration at high speeds.

Observing the printer in action, one can appreciate how continuous rotation simplifies acceleration profiles. Instead of stopping and reversing, the disks can spin fluidly, potentially improving surface finish and shortening print times. Yet this approach also demands careful coordination of angular velocities to maintain consistent extrusion rates, a control challenge that has clearly been tackled with thoughtful firmware tuning.

From my vantage point, integrating inverse SCARA mechanics with an automatic toolchanger could reshape how makers approach complex parts. Imagine printing a living hinge with one tool, switching to a hardened filament for structural elements, and finishing with conductive ink in a seamless operation. Such versatility not only pushes the limits of what desktop devices can achieve but also encourages fresh applications in prototyping and education.

In conclusion, the melding of polar coordinate motion, inverse SCARA geometry, and automated tool swapping highlights the ongoing spirit of experimentation in the maker scene. By stepping away from conventional Cartesian layouts and embracing rotational kinematics, this design lights the path toward more compact, efficient, and multifunctional 3D printers. It’s a reminder that innovation thrives when we question assumptions and spin our ideas in new directions.